Artificial Intelligence: Quality Prediction of Chemical Products in the Production Process

- by 7wData

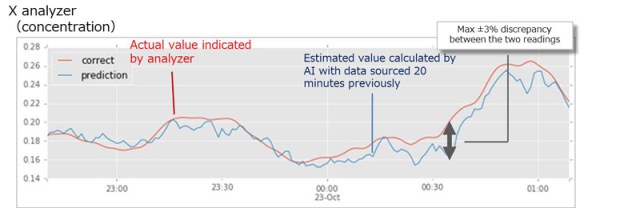

NTT Communications Corporation and Mitsui Chemicals, Inc. announced that they have successfully created a technique that accurately and speedily predicts the quality of gas products. The technique is based on the modeling of the relationship between the different data sets sourced from raw materials feeding into the reactor and reactor conditions, and X gas concentrations which represent gas product quality.

The data is analyzed using Deep Learning algorithms, an artificial intelligence (AI) methodology that automatically processes relevant factors in order to model and predict outcomes. In the gas production process, these factors are represented by 51 types of time-based process data such as temperature, pressure, and flow. The end result is a highly accurate forecast of the quality of the resulting gas products.

Using their new modeling process, the two companies have succeeded in keeping discrepancies between the concentration of X gases predicted by this model and the actual concentration of X gases within +/-3 percentage points in full scale.

Improving the prediction accuracy of X gases concentration by deploying this model, operators of chemical plants will be able to detect faulty sensors or measuring instruments and accurately assess the current and likely future condition of the plant, as well as any anomalies in the chemical product. This will improve the accuracy of alerts, leading to safer and more stable operation and to smarter maintenance of plants.

Mitsui Chemicals is studying feasibility of applying next generation production technology to smart plant maintenance, make operations safer and more stable, establish optimum multi-grade production systems required in high value-added strategy, and share operational knowledge required in globalization. Mitsui Chemicals will conduct researches of next generation production technology including IoT, big data, and AI for enhancement of equipment reliability and operating efficiency and continue to expand production technology infrastructures to respond flexibility to changes in the business environment.

In conjunction with the Virtual Engineering Community, NTT Com has been conducting verification tests to develop cloud and network environments that deliver improved plant productivity and more efficient maintenance procedures since March 2015. Though there are few cases where IoT data analyses deliver specific benefits in actual production so far, this achievement can be a key technology for efficient production.

[Social9_Share class=”s9-widget-wrapper”]

Upcoming Events

Evolving Your Data Architecture for Trustworthy Generative AI

18 April 2024

5 PM CET – 6 PM CET

Read MoreShift Difficult Problems Left with Graph Analysis on Streaming Data

29 April 2024

12 PM ET – 1 PM ET

Read More