Paging Dr. Robot: How Robotics Is Changing The Face Of Medicine

- by 7wData

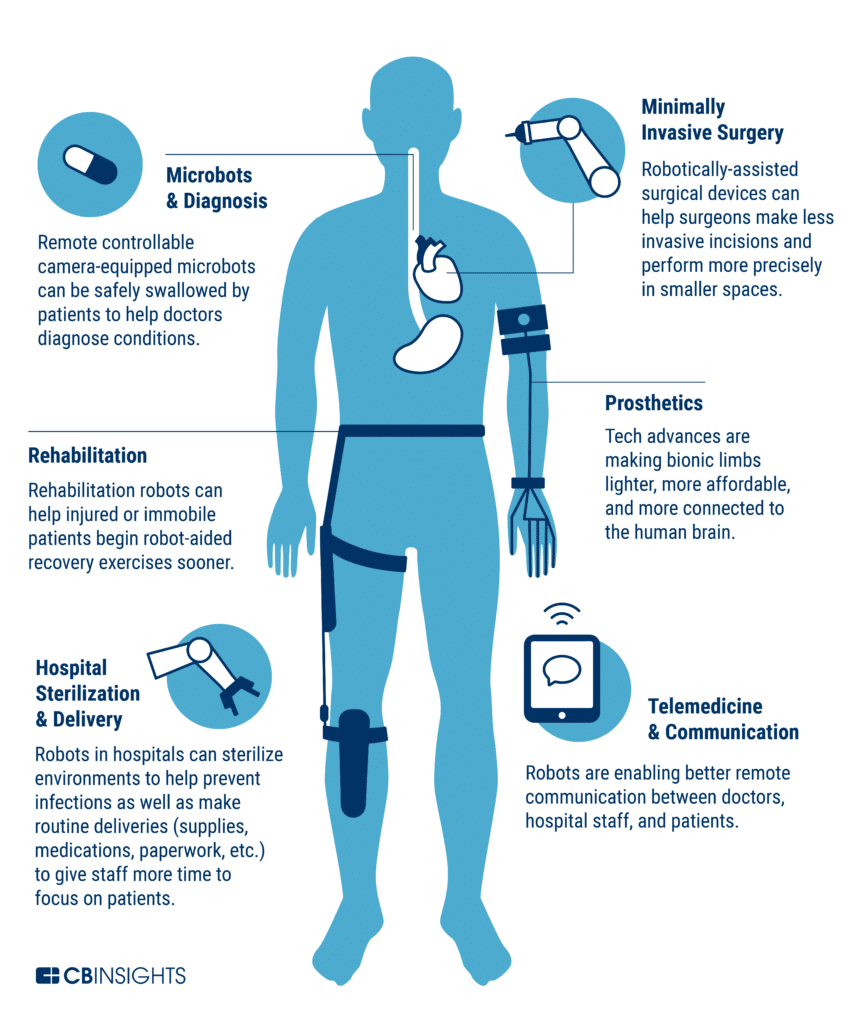

Several industries are seeing the impact of robotics — and medicine is no exception.

While the progress of these applications has been slow compared to other industries, the impact could be huge: robotics in medicine can help to reduce human error, improve recovery time, and reduce hospital stays, ultimately enhancing patients’ quality of life.

The first medical robotic application appeared in 1985, when an early robotic surgical arm assisted in a neurosurgical biopsy surgery. Fifteen years later, the first fully FDA-approved system (known as the da Vinci surgery system) for laparoscopic surgery emerged, giving surgeons the ability to control surgical instruments indirectly via a console.

Today, companies are leveraging advances in the tech to develop new robotic applications to explore the future of medicine — including those related to bionics, disease discovery, and rehabilitation.

Elon Musk’s Neuralink, for example, is working to develop cutting-edge technology to give amputees a better connection to their prosthetics. Auto giant Toyota is developing solutions to serve an aging population, while Johnson & Johnson is heavily investing in medical robotics.

In this analysis, we’ll dig into whether reality is matching those big ambitions, and dive into applications where medical robotics are beginning to enter the mainstream.

From bionic body parts to microrobots you can swallow like pills, robots are coming to a hospital near you — no medical degree required.

When it comes to surgery, robotics is mostly serving as a high-tech surgical assistant that can help doctors perform minimally invasive surgeries — especially in hard to reach or micro areas.

Most of these systems, classified as robotically-assisted surgical (RAS) devices by the FDA, allow surgeons to perform operations using a console that operates surgical arms, cameras, and other instruments that perform the procedure.

RAS systems can result in fewer and smaller incisions, lowering the likelihood of blood loss and infections — which often translates into less pain and fewer complications for patients.

Given these benefits, surgical robot systems have seen huge growth over the last decade.

Notably, one of the most popular robotic tools is also one of the oldest: the da Vinci surgery system. However, it’s seeing an increasing number of competitors on the scene.

RAS systems are poised to make a significant impact on orthopedics.

This “robotic revolution” kicked off in earnest in late 2013, when medical technologies firm Stryker bought Mako Surgical, maker of devices for knee and hip replacement surgeries, for $1.65B.

Mako’s system can create a 3D model of a joint based on a CT scan, allowing the surgeon to pre-operatively plan for each individual patient. The plan is then loaded into the system and adjustments are made as needed. Once the plan is set, the robotic arm sets the angle and plane of the surgical saws and prevents cuts from going too deep.

In 2018, the Mako system performed nearly 80,000 knee and hip replacements in over 650 locations.

Seeing the potential, the orthopedics arms race is on, as some of the biggest names in the industry work to develop better — and smaller — devices to assist surgeons and improve results while being more cost-effective. (For reference, the Mako device costs an estimated $1M.)

One brand that has been a big player in medical robotics is Johnson & Johnson. While the company has made some significant investments in medical robotics over the last few years, orthopedics is a primary area of focus. In an effort to create a direct competitor to the Mako system, Johnson & Johnson’s orthopedics business, DePuy Synthes, acquired Paris-based Orthotaxy.

Orthotaxy has created and developed a surgical robot prototype the size of a shoe box to assist on knee surgeries. Its small size (and smaller price tag) may be a differentiator in the market.

[Social9_Share class=”s9-widget-wrapper”]

Upcoming Events

Evolving Your Data Architecture for Trustworthy Generative AI

18 April 2024

5 PM CET – 6 PM CET

Read MoreShift Difficult Problems Left with Graph Analysis on Streaming Data

29 April 2024

12 PM ET – 1 PM ET

Read More