Applying Machine Learning to Manufacturing

- by 7wData

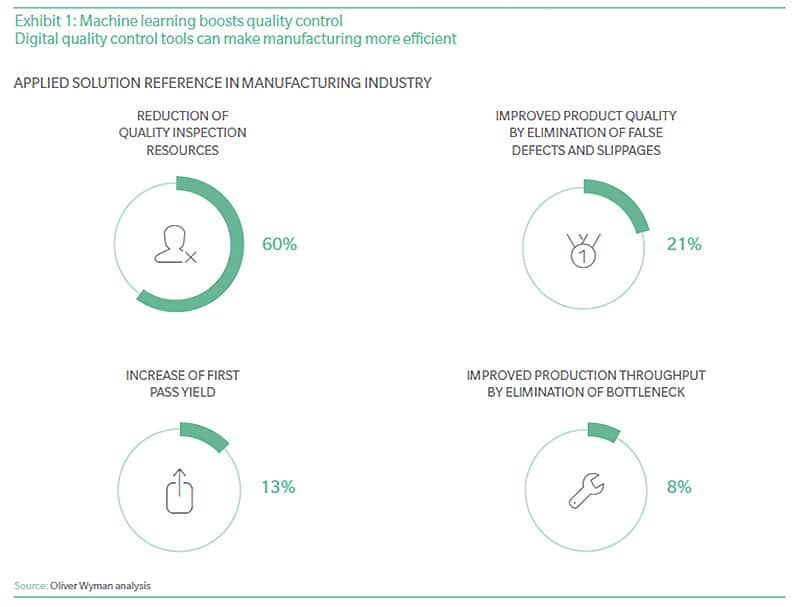

If manufacturers want to sustain and grow their customer bases in a competitive environment, their products need to fulfill increasingly high quality and reliability standards. Automakers, for example, now have a target defect rate for the integrated systems of less than 1 percent.

That’s putting pressure on the original equipment makers (OEMs) and their suppliers who have to meet these targets at the same time that products and manufacturing processes are becoming increasingly complex and featuring numerous activities that impact quality, performance, and yield. To prevent failures of components, systems, and ultimately the product, these manufacturers need reliable methods to find defects.

But quality control today is, in many cases, still performed by human inspectors, which limits its reliability and efficiency. Components such as turbine blades and welded joints are highly safety-critical, and their manufacturers typically perform quality inspection with systems such as 3-D CT scanning that produces images in 100 or more layers.

Inspectors then examine each of these for possible defects, such as porosity or shrinkage. But it’s often difficult for people to distinguish correctly between a defect and image noise—random variations of brightness or color caused by something other than the object being examined. Some inspectors may be less skilled than others, and any inspector is subject to human error. As a result, complex defects can be either missed or detected very late in the manufacturing process. This lowers yield, increases the amount of rework needed, and can even lead to field failures.

Advanced analytics based on the exploitation of big data provides an innovative approach for digital quality management. In machine learning, a neural network generalizes historical quality-control data and thus learns to identify defects such as porosities in casted parts.

[Social9_Share class=”s9-widget-wrapper”]

Upcoming Events

From Text to Value: Pairing Text Analytics and Generative AI

21 May 2024

5 PM CET – 6 PM CET

Read More